Researchers from the Digital Cellulose Center have developed a bio-based sensor that can detect both humidity and moisture inside the wood, as well as in the surrounding area. Using these sensors can lead to more sustainable buildings as well as help prevent moisture damage and hazardous mold.

“These sensors can lead to more sustainable wooden buildings and other constructions without relying on critical materials. At the same time, they become easy to handle at end of life, since they do not need to be separated from the wood and can instead follow the usual recycling or destruction flow like other wooden materials”, says Jesper Edberg, Scientific Leader at the Digital Cellulose Center.

The use of wood in construction has resurfaced due to growing concerns over the environmental impact of concrete. However, wood absorbs moisture from its surroundings, leading to rotting, molding, and other kinds of damage. In Sweden alone, the cost of repairing water damage in buildings exceeds 500,000,000 euros per year. To address this issue, researchers within the Digital Cellulose Center have developed a bio-based graphene sensor embedded in wood that can detect both ambient humidity and moisture inside the wood.

The traditional method of determining moisture in wood involves a two-point probe system where conductivity or capacitance is measured between two metallic probes placed over, or inserted into, the top layer of the wood. Such a system is invasive and demands mostly manual measurement.

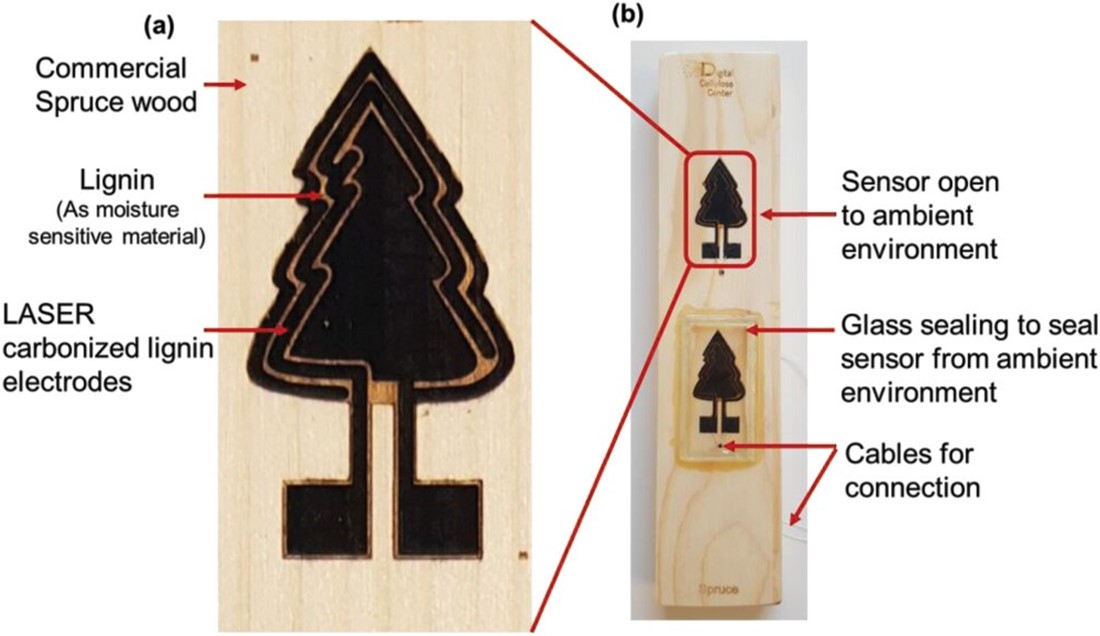

In this work, the researchers instead fabricated the moisture sensor directly on wood using laser patterning with the goal of achieving more accurate sensor reading and the possibility of remotely monitoring the moisture over the entire lifetime of the wood element. At the same time, biobased materials are used to fabricate the electrodes of the sensor and also the active sensing material, that is lignin.

The Digital Cellulose Center (DCC) aims to make forest-based materials and products part of the digital world via sustainable electronics and the circular economy. “The graphene humidity and moisture sensor has really demonstrated a sustainable way for electronics and has raised a high interest from both the Digital Cellulose Center’s academic and industrial partners,” says Ursula Hass, Centre Director at the Digital Cellulose Center.

a) Spruce wood coated with lignin ink and graphitized contacts forming interdigitated electrodes (IDE) in the shape of a tree, separated by non-graphitized lignin acting as moisture sensitive material. b) Two sensors fabricated on a wood surface, one sealed from front side, while the other was kept open to ambient environment.

Creating bio-based sensors with lignin

In this “Lignography” method, the team patterned sensors using a printable ink composed of lignin – a complex organic polymer found in the cell walls of many plants and a byproduct of the paper and pulp industry – and cellulose, which were converted into graphite or graphene upon irradiation with a laser beam.

“Lignography is a technique that we developed to be a more sustainable alternative to fossil-based carbon in electronics. With this work, we have taken the research one step further in demonstrating a fully bio-based sensor system that can help prevent moisture damage in buildings”, says Jesper Edberg.

Following the graphitization process, these sensors were able to measure humidity levels in a range from 10 percent to 90 percent at 25 degrees Celcius in different types of wood. The sensors fabricated on spruce and pine wood exhibited high sensitivity, with values of 2.6 and 0.74 MΩ for every 1 percent increase in humidity, respectively. Finally, the researchers showed that the changes in humidity collected by these sensors can be remotely read through a connected computer or visualized with a simple LED system.

Demonstration of portable sensor readout system with an LED indicator. The LEDs turn on from green to red with increasing humidity level.

The researchers have also demonstrated lignin graphitized electronic components, such as resistors and triboelectric energy harvesters, involving similar “lignography” processes.

“The research from our group paves the way for the development of bio-graphene-based sensors, energy harvesters, and electronic devices and circuits based on sustainable and recyclable materials, such as wood and paper. By utilizing these materials that can be discarded in paper bins, we hope to eliminate the need for electronic bins,” explains Mohammad Yusuf Mulla from RISE.

The team prepares the smart lignin-based materials by chemically modifying lignin into either thermoset or thermoplastic formulations. Functional additives such as BaTiO3 and reduced graphene oxide are added to these composites. When an external force is applied to a BaTiO3 crystal, the crystal structure is distorted, causing its positive and negative charges to separate and generate an electric field. At the same time, graphene – an excellent conductor of electricity – boosts the conductivity of lignin-based composites allowing for the efficient transfer of electrical charges. Compared to lead-based commercial piezoelectric materials, lignin-based materials are safer and more sustainable additives for touch and pressure sensors.

“Thanks to novel materials like graphene, we envision a future generation of materials that could be extracted from wood instead of petroleum and do interesting things with a tap of our fingers,” says Abhilash Sugunan from RISE.

The study was conducted by researchers at RISE and Linköpings universitet with support from Stora Enso. The research is based on previous findings in “Laser-induced graphitization of a forest-based ink for use in flexible and printed electronics.”

Research Institutes of Sweden (RISE) is an Associated Member of Graphene Flagship. Read the full article on the Graphene Flagships website.

Watch Jesper Edberg demonstrate the bio-based sensor in LignoCity’s webinar: