Projects

The Digital Cellulose Center aims to develop sustainable electronics using renewable forest materials. After a successful mid-term evaluation, the center is now on its second phase which will continue until 2027. In this new phase, DCC is focusing on three value chains that are relevant for industrial partners and society: energy storage, medical and health technology, and digitalization (including Internet-of-Things). Now in the second phase of DCC, the center is also strengthening its fundamentals by becoming even stronger within lignocellulose chemistry and green printed electronics. This will enable the design of novel electroactive materials and structures that can be addressed through digital communication. Moreover, the center is widening the technology readiness level (TRL) range by engaging in demonstrator and scalability projects, which will facilitate the transfer of knowledge and competence from the center to the industry and society. The center is also addressing the cyclability and sustainability aspects of the digital cellulose products, such as design for recycling, life cycle assessment, and environmental impact. This will contribute to the vision of a circular economy and a sustainable society.

The DCC is running 6 projects.

- Project 1: Biobased Carbons and Cyclability of DCC materials.

- Project 2: Energy Storage.

- Project 3: Materials design on a fibre level.

- Project 4: Сellulose based membranes for selective transport at molecular level

- Project 5: Sensors and actuators integrated in cellulose.

- Project 6: DCC Demonstrators – a cross theme project.

Project 1: Biobased Carbons and Cyclability of DCC materials

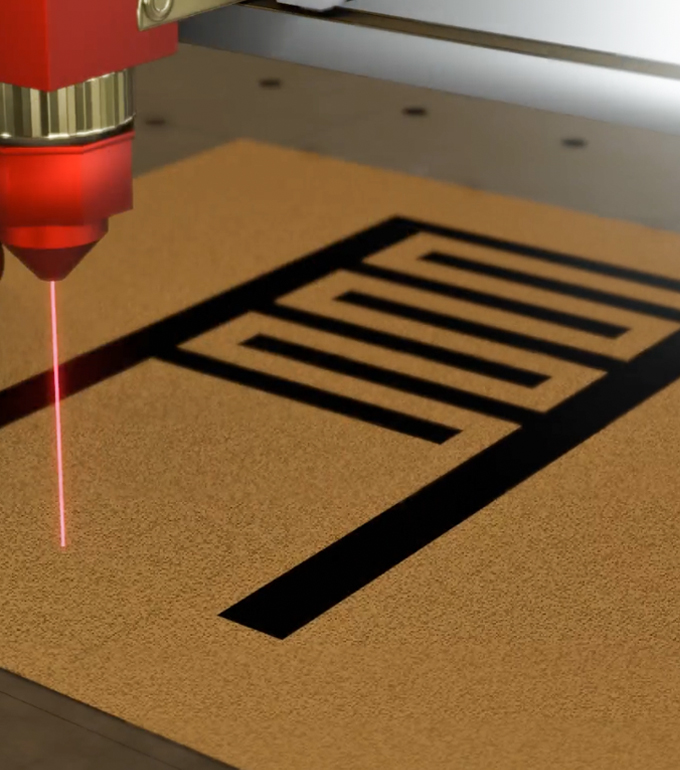

In the first phase of this project cyclability design guidelines were defined, LCA for selected electrical components produced from DCC materials were performed, the carbonization of bio-based materials such as lignin or cellulose were explored, as well as their integration within electrically active components (i.e. electrode for energy storage conductive tracks and sensors).

During the second phase, the goals are to further explore the carbonization and graphitization of lignocelluloses, achieve properties with high conductivity, barrier properties, or sensor functionality, understand the industrialization and scalability of biobased carbons, and integrate them within medtech & health, energy storage, and the Internet of Cellulose Things. Additionally, the phase aims to identify how DCC materials and processes can support or hinder Green Electronics and design solutions for separating and sorting mixed material streams at recycling stations.

Project 2: Energy Storage

This project is focusing on paper-based energy storage in different subprojects, and investigates wood-based materials for supercapacitors, batteries and energy harvesting. The project is also investigating scalable methods for producing energy storage materials and devices, including innovative paper-making techniques.

Project 3: Materials design on a fibre level

The main objective of this project is to clarify the interactions between cellulose-rich materials and electrically active components, in order to rationally design/optimize biobased and biodegradable materials. They are to be applied in fields such as energy storage devices, sensors and actuators. The more long-term objective of the project is the preparation of more advanced materials and devices in which the cellulose-rich materials have been modified in unique and, ideally, industrially scalable ways. This knowledge-based project will serve all other projects of DCC and hence the long-term objective of DCC.

Project 4: Сellulose based membranes for selective transport at molecular level

The aim of this project is to design, prepare, and explore, and, in the long-term, to implement cellulose-based membranes as a greener and cheaper alternative to the existing synthetic membranes.

Cellulose membranes invented during the first phase showed promising behavior in Flow battery (FB), which lead to the foundation of a spin-out company Cellfion AB, in order to further develop, produce, and commercialize these products. The second phase research plans are built on this competence and the know-how acquired during phase one.

Project 5: Sensors and actuators integrated in cellulose

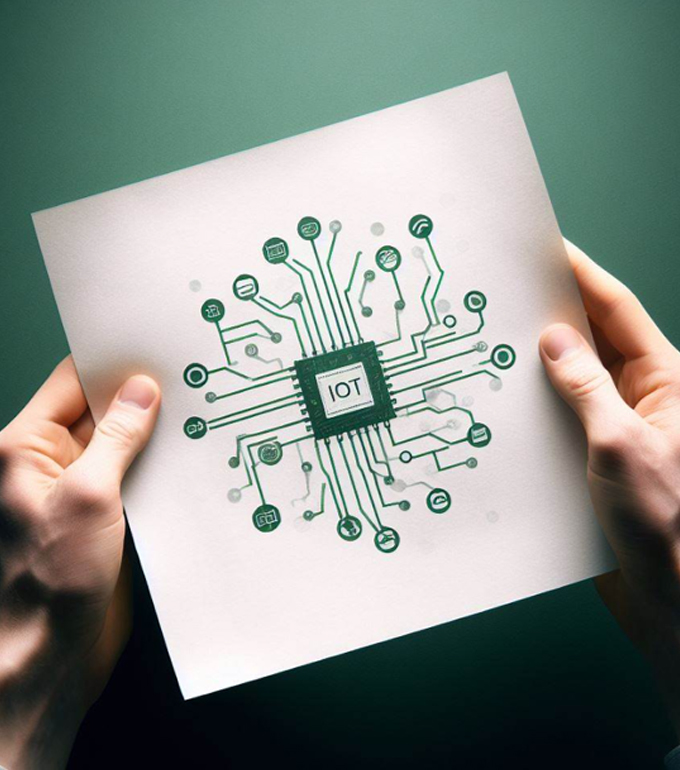

This project aims to study how sensors and actuators can be manufactured and integrated within cellulose products or with cellulose as core material. During the first phase, the focus of this project was the exploration of development of system sub-components such as sensors, actuators, conductive tracks, antennas, and energy harvesting. For each subcomponent, the use of lignocellulose was explored, either as a material component in the device (e.g. fully bio-based energy harvesters and paper displays), or as the environment onto which the device was used (e.g. sensors measuring humidity/moisture in paper, board, or wood).

During the second phase, development will continue for these components, but the focus will shift towards system integration, i.e. connecting all subcomponents developed in phase 1. One of the aims for the coming years is to develop IoT systems on paper, using biobased materials in as many subcomponents as possible, with the goal of limiting the environmental footprint of IoT devices during manufacturing and end of life. For this reason, life cycle analysis (LCA) and sustainability assessments will be important components of the project.

Project 6: DCC Demonstrators – a cross theme project

This project has been designed to translate the R&D results achieved as part of the other projects into demonstrators. The goal is to facilitate technology communication and awareness within DCC, and to become an effective tool for communication and sales activities with customers and valuable target groups. This project also aims to help industrial partners to understand the possible route to achieve the needed TRL level (products), boosting the transfer of the developed knowledge in future internal strategic development projects.